Fastems transforms manufacturing compliance training with Valamis

Fastems, a leader in factory automation, faced low learner engagement, inconsistent training, and compliance challenges across teams and partners.

Background & challenge

Before partnering with Valamis, Fastems, a leader in intelligent factory automation, faced growing challenges in its learning and development (L&D) strategy:

- Low learner engagement across internal teams.

- Scalability issues with training programs.

- Limited visibility into learning outcomes and training effectiveness.

- A fragmented training experience for external partners due to reliance on in-person sessions and inconsistent online platforms.

- Compliance difficulties with ensuring up-to-date certifications across employees and partners.

The Challenges

Fastems, a global leader in intelligent automation solutions for the metalworking industry, recognized the need to modernize its learning and development (L&D) strategy. As the company expanded its operations and customer base, they were challenged with delivering consistent, scalable, and engaging training across a diverse range of internal and external stakeholders.

As Fastems CIO Sami Teininen explained:

“Our biggest pain points were low learner engagement and difficulty in scaling our training programs. We also struggled to track the impact of learning effectively, especially when it came to compliance training.”

Engagement that delivers

Fastems selected Valamis to centralize and modernize their training and organizational development strategy. The rollout began with approximately 600 active users, and usage continues to grow as the platform is introduced to customers and partners.

Valamis quickly proved to be the ideal fit, with features such as learning paths, deep analytics, mobile learning, and seamless system integrations bringing immediate improvements.

“The learning content studio has empowered employees across the organization to create and share educational materials. It’s helped us build a culture of continuous learning,” said Mr. Teininen.

Measurable results in manufacturing

Since adopting Valamis, Fastems has reported significant improvements across its L&D metrics, including:

- A notable increase in training completion rates

- Enhanced learner engagement

- Reduced onboarding time for new employees and partners

- Cost savings through the consolidation of training into a single platform

Using Valamis’ analytics tools, Fastems is now able to effectively measure the success of its learning initiatives:

“We’re seeing higher engagement levels and positive feedback from learners.”

Partner performance and compliance training have also improved. “Partners are more knowledgeable and better prepared, and they’re engaging more with the training programs,” he added.

Beyond engagement, Valamis delivered tangible cost benefits:

“We have achieved cost savings by consolidating our training programs onto a single platform.” Sami Teininen.

Future growth

Fastems is continuing to expand its use of Valamis, particularly with a focus on customer training. Looking ahead, the company plans to take into use more advanced features such as personalized learning paths and AI-driven recommendations.

“We’re excited about how Valamis will continue to evolve with us,” said Mr. Teininen. “Integrations with additional systems are also on the horizon to further streamline the user experience.”

Final advice?

“Valamis has revolutionized our L&D strategy by providing a scalable, engaging, and efficient platform for all our training needs,” concluded Mr. Teininen.

For organizations considering a shift to a modern learning solution, Fastems offers this advice: “Choose a platform that can grow with your needs, provides actionable insights through analytics, and ensures a seamless experience for all users. And don’t underestimate the importance of ongoing support to help partners succeed.”

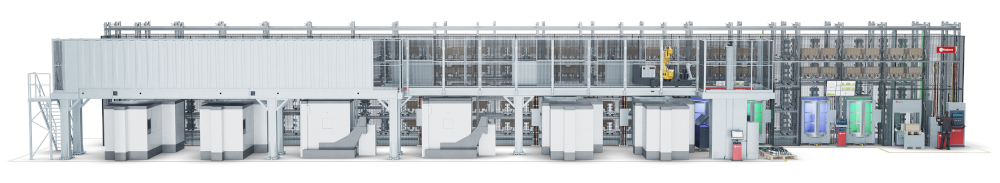

About Fastems:

Fastems is the leading supplier of CNC automation solutions for variable batch production, also known as high-mix, low-volume manufacturing. We’re an open integrator with over 40 years and 4000 installations of experience with 90+ machine tool brands.

Fastems typically automates 3-5 axis milling machines, turning and turn-mill machines, grinding machines and more. Our MMS control connects to various data systems and is praised for its production planning and resource management features that enable you to take control of your production.

Fastems integrates and automates measuring, washing, marking, finishing, and various other devices or processes to be part of our intelligent CNC automation systems. We also offer deburring and robotic finishing cells (RFC) and robotic systems for automated part loading to/from pallets (ALD). Solutions for cutting tool automation including pre-setters, are also included.

Compliance ≠ complicated

Get compliance training right, every time. Just what your team needs, straight from our LMS.

Our compliance solutions